Modification experts: design, installation, production and certification

Ensure the continued airworthiness of the next connectivity installation on your defense, commercial or business aircraft.

Formerly EAD Aerospace, we are industry leaders with more than 20 years of aircraft modification experience. We specialize in customized retrofit installation solutions of cabin and cockpit avionics, for aircraft connectivity such as Satellite Communications (Satcom) and Air to Ground (ATG) systems.

Whether your operation flies commercial, business, or defense aircraft; narrow- or wide-body, helicopters, or another aircraft type, we’ll work with you from start to finish to deliver a complete system that meets your operational requirements and budget.

We offer modification, installation and certification of avionics and connectivity systems, including comprehensive:

• engineering & technical system architecture and design

• component production and manufacturing

• certification services

• full program management

DOA & POA

DOA Part 21 (Design Organization Approval) and POA (Production Organization Approval) holders, we have developed an immense range of FAA and EASA STCs (Supplemental Type Certificates) for a broad number of aircraft rotorcraft types. Learn more about STCs with our catalogue (coming soon).

Our DOA Part 21 and POA areas include avionics and structures. We’ve successfully completed an extensive number of cabin and cockpit avionics, Satcom system retrofit projects, and connectivity system integration and installation.

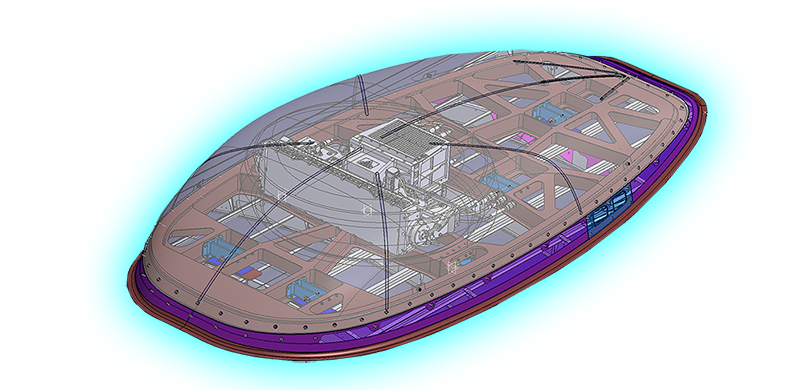

Airborne system retrofit experts, we deliver innovative installation kits for commercial, business and defense aviation markets—both pre-packaged and entirely customized. An excellent example is our SUMS, Satcom Universal Mounting System. A high-performance kit for mounting Ka-band antennas on Airbus and Boeing aircraft, it requires fewer fuselage holes, reduced installation time and less maintenance. You can learn more about this innovative system here.

Satcom Universal Mounting System (SUMS) – Designed & Certified by Eclipse Technics

STCs for an extensive range of airframes :

• Airbus A320, A330 and A340 families

• AS 350 /355 / 365 EC120/130

• ATL2

• ATR families

• A109

• Beechcraft King Air 350 ISR

• Bell 206 (L, L4T)

• Boeing B737 classics, NG, MAX B757, B767, B777, B747

• Bombardier, Global Express and Dash-8

• C-130

• H500

• E-3

• Twin Otter

More about Eclipse Technics

Leading end users operating 1000s of aircraft trust Eclipse Technics expertise :

• Qatar Airways

• Air New Zealand

• Philippines Airlines

• Singapore Airlines

• Ethiopian Airlines

• British Airways

• Iberia

• Vueling

• Fedex

• DHL

• SAS

• Saudia Airlines

• Brussel Airlines

• Royal Air Maroc

Areas of expertise :

Our expertise encompasses design, engineering and project management, component production and certification. Whether your aircraft flies commercial, business, defense aircraft, we’ll work with you from inception to completion to provide a system that meets your operational requirements and budget.

Core strengths :

• POA since 1998

• DOA since 2003

• In-depth experience, covering airlines, defense and business aviation

• Production facility based in southern France

• Design and study capabilities

• Multiple worldwide certification capabilities

• Part21 and FRA21 Agreement

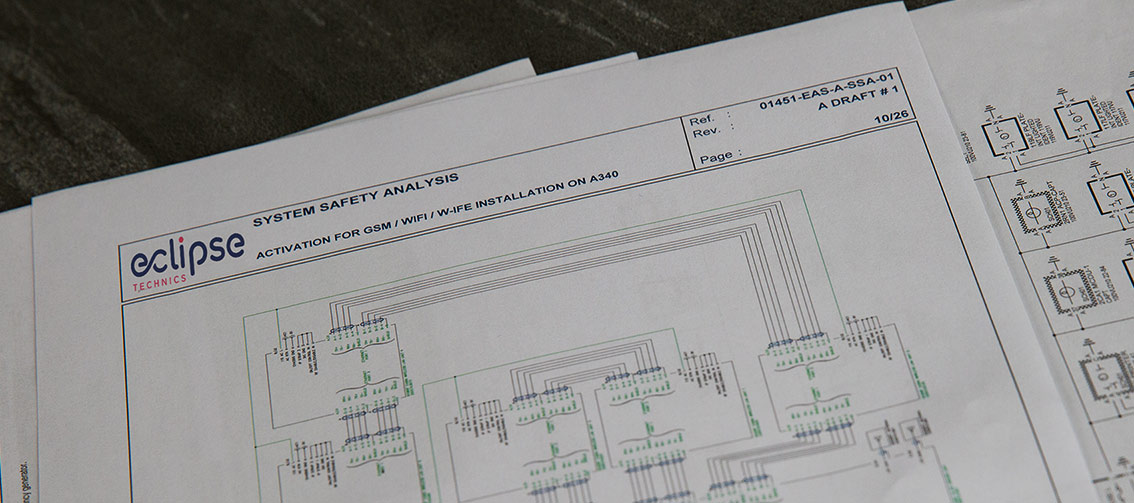

Design and project management

We will take your requirement and assess your aircraft and needs to identify and mitigate risk. We offer comprehensive support on your retrofit project with our holistic approach to aircraft-retrofit projects which includes a detailed technical evaluation of your options. More than 20 years of planning, budgeting, project management services which includes monitoring and control; materials and equipment selection, installation and certification, ensures we deliver the highest quality solution on time and within budget.

Our project managers help reduce implementation time and risk through standardized, tested, repeatable engineering processes, and consistent implementation through a field-proven approach and standardized methodology.

Certification

Having achieved POA (POA # FR.21G.0119) in 1998, Eclipse Technics (then EAD Aerospace) was the first independent company to apply for DOA—obtaining approval in 2003 (DOA # EASA.21J. 053). And since 2017, through our FRA21J-015-DGA approval, we are an accredited Aviation Design Organization (ADO) for the French army (DGA: Direction Générale de l’Armement).

Since obtaining our first FAA STCs, we have added multiple worldwide aviation authority certifications to our catalogue:

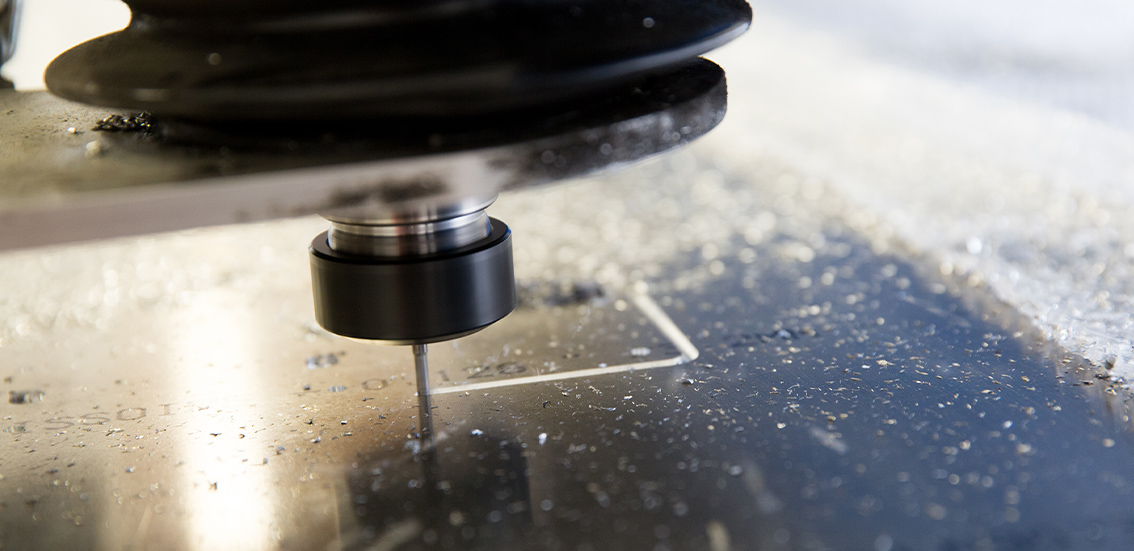

Production

Under our DOA and POA, we develop serial avionics prototype products for OEMs and MROs. Our manufacturing capabilities for various Satcom, connectivity and avionics projects support and complement connectivity installations.

Manufacturing

Our team of specialists have in-depth experience in technology manufacturing and a worldwide network of supplier partnerships and subcontractors. We work diligently to ensure they meet the same strict standards as we expect from our own production.

With a production facility situated near Marseille-Marignane airport, our POA encompasses the manufacture of mechanical and structural parts for installation on aircraft, and the manufacture of metallic and non-metallic parts. Parts range from mounting structure solutions for avionic components to metallic parts used in aircraft cabin interiors or cargo compartments. We also specialize in the manufacture and test of RF Cables and complex Wire Harnesses, providing turn-key fabrication to demanding aerospace specifications. We provide laser wire marking and over braiding (metal and fabric) when required. Our manufacturing capabilities include:

• Coaxial cable assemblies

• Multiconductor cable assemblies

• Harness and discrete wire assemblies

• Flat ribbon cable assemblies

• Molded cable assemblies

• Small pitch assemblies

• Military and aerospace cable assemblies

• Fiber optic assemblies

• Avionics bays assembly and cabling

We are proud members of :